Thanks srm for all your advice and guidance, it's been invaluable. I will probably scuff up with 320 grit and put a coat of paint on my rudders soon. I'm still pretty confident that extensive UV damage and poor surface prep were the cause of my original issues.

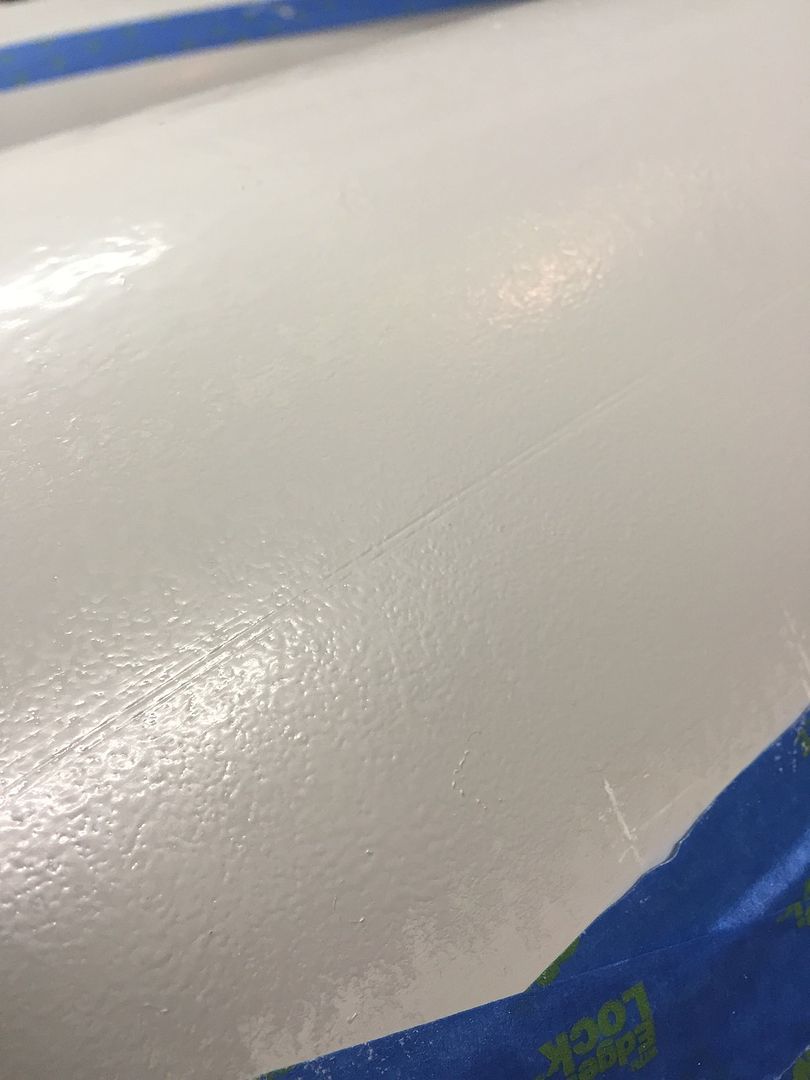

I ended up just sanding my bottoms fair and leaving them. So far it seems to be adhering. Hopefully I got some amount of chemical bonding between the two coats. Some pictures below:

My gel coat color matching wasn't quite perfect, but it's close enough! If you're more than 10 feet away, you can barely notice the difference! It's the bottom, anyway, haha.

Why don't they look as shiny right side up!?!

I used a $40 variable speed buffer from Harbor freight, wool & foam pads, 3M Rubbing Compound & 3M Finesse-it II, and wow, what an improvement!

All in, it was ~$280 for materials & tools for the fiberglass, gelcoat & buffing, and another ~$200 for the rudders. Damn that stuff adds up quick!

A few lessons learned for next time (hopefully a LONG time away!)

Rudders:

1) Sanding graphite & epoxy makes a mess!

2) Sanding epoxy is tough, but a power sander and low grit sandpaper will burn through it faster than you think

3) Bubbles are unavoidable. Mixing in graphite entrains air in and of itself! But stirring slowly with a popsicle stick and applying/drying in direct sunlight helps thin & smooth the finish.

4) Foam Roller followed by foam brush to smooth the surface is the way to go!

5) When resurfacing, you will find soooo many more surface imperfections than you ever knew you had!

Hulls:

1) Don't forget that polyester resin/gelcoat shrinks as it cures. When applying fiberglass cloth, always cut 1 or 2 more pieces than you think you need.

2) Just because there's glass showing doesn't mean you need new glass on the bottoms. Check the shape of the hulls using a template before planning the repairs.

3) Applying gelcoat on thick doesn't pay. You've got to sand more, which takes off all the extra gelcoat you put on!

4) Brushing gelcoat on seems to result in a better finish, but rolling covers more area. If rolling, use very light pressure!

5) When gelcoat starts to gel, quickly trying to put more on just makes a mess of the finish!

6) Curing polyester/gelcoat is STRONG. I'm finding dead bugs everywhere!

- Some well ventilated space not attached to your house is advisable.

6) Don't sand too much with the low grit paper, remember there's a long way to go! Sand up to 1500 grit using very gradual steps. Skimping on the sanding, especially with the higher grits will leave visible scratches in the finish!