scharrow wrote:

Great articles. I need to get subscribed to the HOTLINE.

Start here -

http://www.regattanetwork.com/membermgm ... n_form.phpA $20 recreational / SUP membership is essentially a HOTLINE subscription.

scharrow wrote:

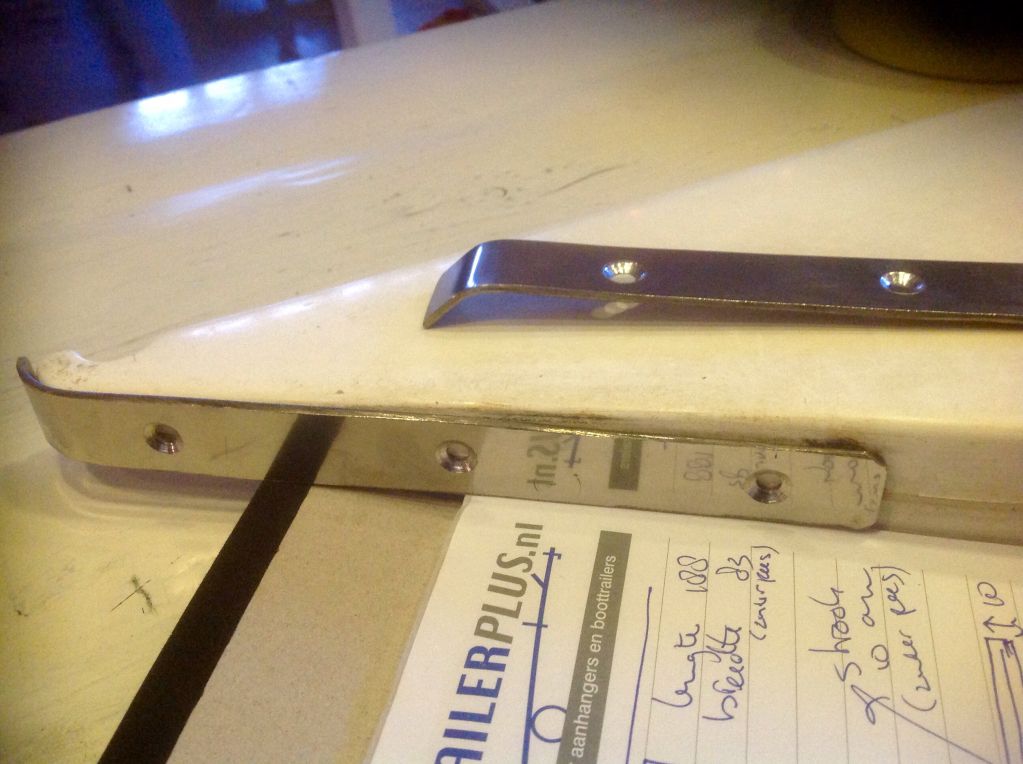

My hooks aren't broken, but one does have a small stress crack. My idea was grind them down a little and use a couple of neatly trimmed pieces of cloth and west system epoxy, build them back up, then sand them down to the correct width.

The hook is the highest stress area on the whole board. The strength in it is not in the outer skin, but the glass rope that's laid into it during the manufacturing process. In the first article, there's a section called "Preemptive Repairs" that shows how to deal with this by inserting a carbon fiber rod into the backbone of the centerboard. It's cheap, easy and your hook will never break off.

scharrow wrote:

My leading edges are wore and the two tips are shortened one more than the other. My idea here was to cut a slot down the leading edge, clean out the tips and rebuild them from the inside out using west system epoxy, adding cloth on the final layers.

There's no need to build up with cloth on the edges, unless the foam is exposed. It adds no strength and is only marginally abrasion resistant (which is what you need). Slot the edge and glue in a spline (either of glass carbon sheet) that's the original outline of the board and build up to it with WEST System thickened with colloidial silica (407) to a peanut butter consistency. The spline gives you a guide to shape the edge to.

BTW, WEST resin must be protected from UV, else it turns amber and gets brittle. That means painting or using pigment in the mix.