Got the mast back today from the dealer.

Went to fit it in the receiver.

Hold the phone.

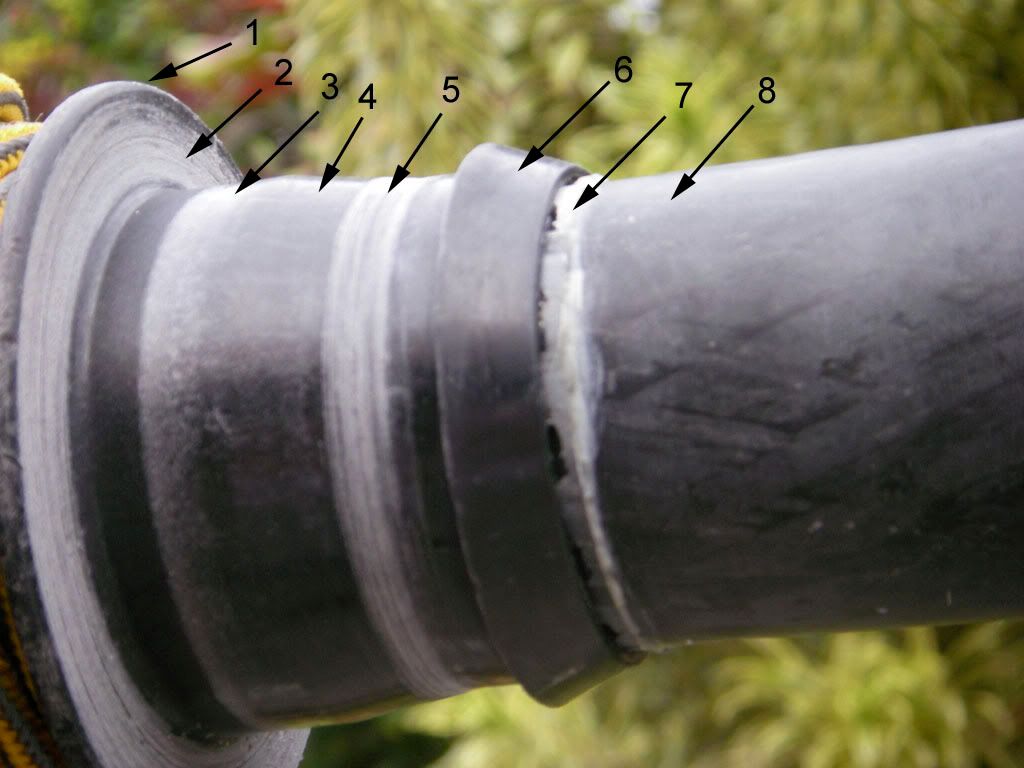

The internal pin that fits into the bottom of the mast had rusted off! Thats' the small bolt like protrusion from the metal plate held in by four screws.

Definitely the reason I saw the mast moving with the sail furled and probably the reason the furling drum collar got pushed up. The bottom of the mast had nothing to ride on, but the plate itself.

I also noticed that the pin must have been hollow and appeared to be welded to the plate. The remains showed a cylinder, not a sold pin, along with clear corrosion. Weld failure might also be a possibility although I don't think so. The thing will have to be disassembled to find out.

I didn't get a picture yet, but will tomorrow when I hit the water.

I believe this has to be a warranty item. I'll need part 79514101 '08 Mast Receiver and 71320001 Gasket to replace it. I have asked the dealer to check with Jacques.

I can do the replacement myself, and if Hobie wants, return the old receiver to the dealer to ship to Hobie for inspection of the plate.

While I wash the boat all the time, sometimes it's on top of the truck so salt might have accumulated in there. I'd make sure yur receiver is flushed out thoruoghly. I'll start adding a squirt of WD40 to the maintenace list also.